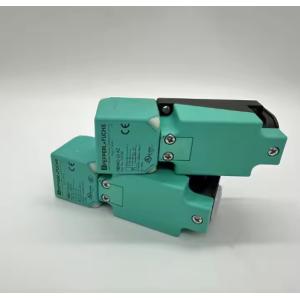

The Pepperl+Fuchs NBB20-U1-A2-F-V1 is a high-performance inductive proximity sensor engineered for reliable non-contact detection of metal objects in industrial automation. Featuring a 20 mm rated operating distance (flush mounting) and a bidirectional, rotatable sensor head, it enables flexible alignment and precise positioning in compact or complex setups. The 4-wire DC PNP output offers complementary switching (NO/NC configurable), operating seamlessly across a 10–30 V DC range with reverse polarity and pulsing short-circuit protection. Four 360° visible LEDs—green for power and yellow for switching state—allow intuitive real-time diagnostics. With a 440 Hz switching frequency and 5% hysteresis, it minimizes signal fluctuations, delivering stable performance for high-speed applications like conveyor systems, robotic positioning, and part counting.

Built to withstand harsh conditions, the NBB20-U1-A2-F-V1 incorporates a durable PA/metal housing with an epoxy powder coating, resisting corrosion, impact, and vibration. Its IP68/IP69K protection rating ensures full dustproof and waterproof performance, capable of enduring high-pressure jet cleaning and prolonged submersion, making it ideal for wet, dusty, or high-contamination zones. The sensor operates reliably from -25°C to +85°C (ambient) and stores safely at -40°C to +85°C, adapting to extreme temperature variations. Mechanical design highlights include screw terminal connections (supporting up to 2.5 mm² conductors) and a compact 40 x 40 x 118 mm form factor (225 g), simplifying installation in space-constrained or vibration-prone machinery.

Designed for seamless integration into industrial systems, the NBB20-U1-A2-F-V1 complies with EN IEC 60947-5-2 safety standards and carries certifications like cULus listing and RoHS compliance, with CCC exemption for ≤36 V DC applications. Metal reduction factors (aluminum: 0.33, copper: 0.31, stainless steel 304: 0.74) allow adaptable detection across various materials, enhancing versatility in automotive manufacturing, logistics, and process control. Functional safety parameters include an MTTFd of 1289 years and a 20-year mission time, ensuring long-term reliability in non-safety-integrated setups. Supported by 3D CAD models and EPLAN data, this sensor combines precision, durability, and ease of use, making it a trusted choice for demanding industrial automation workflows.

|

Attribute

|

Specification

|

|

Product Type

|

Inductive Proximity Sensor

|

|

Detection Principle

|

Non-contact metal detection via inductive sensing

|

|

Rated Operating Distance

|

20 mm (flush mounting)

|

|

Assured Operating Distance

|

0–16.2 mm

|

|

Output Type

|

4-wire DC PNP (complementary switching, NO/NC configurable)

|

|

Voltage Range

|

10–30 V DC

|

|

Switching Frequency

|

0–440 Hz

|

|

Hysteresis

|

Typ. 5%

|

|

Reverse Polarity Protection

|

Yes

|

|

Short-Circuit Protection

|

Pulsing

|

|

Voltage Drop

|

≤2 V

|

|

Operating Current

|

0–200 mA

|

|

LED Indicators

|

4 x 360° visible LEDs (green: power; yellow: switching state)

|

|

Connection Type

|

Screw terminals (supports 0.5–2.5 mm² conductors, 1.2 Nm tightening torque)

|

|

Housing Material

|

PA/metal with epoxy powder coating

|

|

Sensing Face Material

|

Polyamide (PA)

|

|

Degree of Protection

|

IP68/IP69K (dustproof, waterproof, and resistant to high-pressure jet cleaning)

|

|

Ambient Temperature

|

-25°C to +85°C (-13°F to +185°F)

|

|

Storage Temperature

|

-40°C to +85°C (-40°F to +185°F)

|

|

Dimensions

|

40 mm (W) x 40 mm (H) x 118 mm (L)

|

|

Weight

|

225 g

|

|

Metal Reduction Factors

|

Aluminum: 0.33

Copper: 0.31

Stainless Steel 304: 0.74

|

|

Functional Safety

|

MTTFd: 1289 years

Mission Time (T<sub>M</sub>): 20 years

|

|

Standards & Approvals

|

EN IEC 60947-5-2

cULus listed

RoHS compliant

CCC exempt (<=36 V DC)

|

|

Typical Applications

|

Conveyor systems, robotic arm positioning, part counting, automotive manufacturing

|